[CODE_4]: MEDIA_ELEMENT_ERROR: Format error

The scooptram are specially suitable for mining operations in narrow, low-lying laneways and difficult mining areas.It adopts a closed static pressure stepless variable speed drive system composed of variable plunger pump and variable plunger motor, stable and comfortable operation, high production efficiency.This model adopts wheel cyclotron support structure, low failure rate.

It can be used to shovel soil, sand, lime, fly ash, animal feces and other bulk materials. It can also be used for light shoveling operations such as ore, sand and gravel.

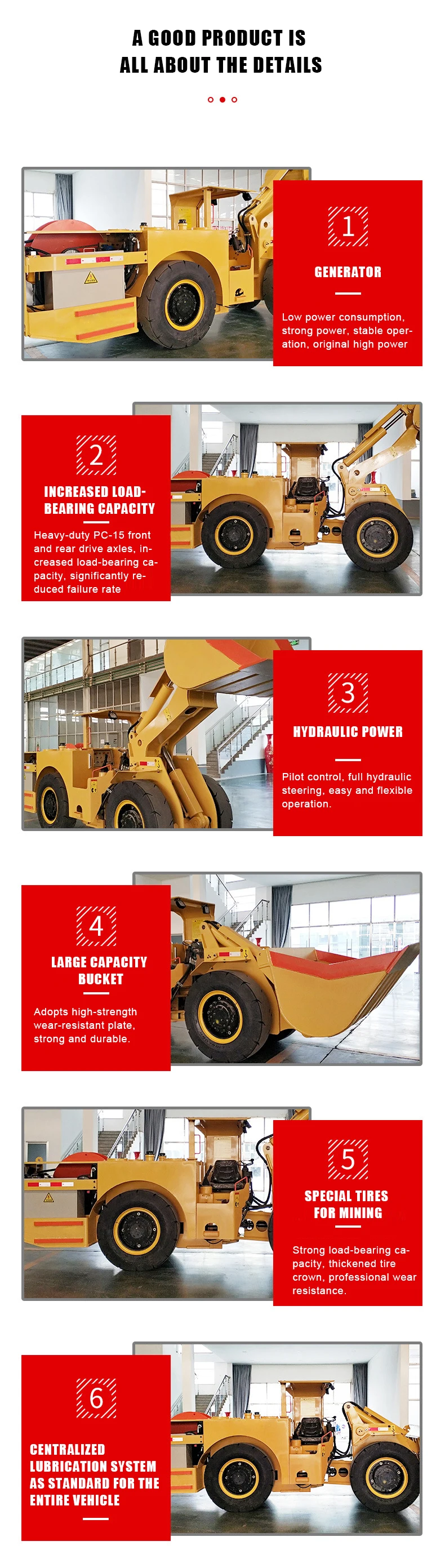

› 1.Adopt Danfoss' latest generation 90 series variable hydraulic pump and variable motor. Danfoss hydraulic system is an internationally renowned brand with low failure rate and perfect matching. It is the best match with 225 motor, which can give full play to the maximum efficiency of the motor, effectively guarantee the service life of the whole vehicle and axle, reduce maintenance costs, and improve equipment attendance rate and mining efficiency.

› 2.Carefully developed and original latest generation cable winding servo follow-up system ensures that the cable can keep pace with the whole vehicle regardless of the transportation state, better protect the cable from accidental damage, and effectively extend the service life of the cable.

› 3. The whole vehicle frame and plate use Q345B low alloy steel as the main material of the frame. The yield lower limit of this material is about 345Mpa, which can withstand various loads from inside and outside the vehicle. Not only is the strength guaranteed, but it also undergoes seven processes of normalizing, aging, sandblasting, and anti-corrosion welding, so it meets the requirements of the frame and working device for structure, power, movement, etc.

› 4. The drive axle uses a heavy-duty 30-axle, which is stronger and more durable than the light-duty axles of other manufacturers, has high impact resistance, reduces the failure rate, and has doubled reliability and safety. It is suitable for complex underground road conditions and shoveling conditions.

› 5. The copper sleeve of the whole machine uses high-strength brass and radially embeds orderly arranged cylindrical graphite fillers as friction materials. The embedded solid lubricant is easy to form a lubricating film, which plays a great role in its friction and wear performance. It has the advantages of high precision, strong bearing capacity and good wear resistance.

› 6. The pin shaft is made of 40Cr alloy steel, which needs to go through 5 processes including rough turning, tempering, fine turning, quenching and fine grinding to ensure the stability of the pin shaft during the working period.

› 7. The hydraulic oil tank adopts pickling, phosphating and high-pressure treatment technology, which is different from the manual cleaning of other manufacturers, thereby ensuring the cleanliness of the hydraulic system and making the pump and motor last longer.

› 8. The swing design of the rear axle with an intermediate slewing bearing is adopted, which has a more reasonable structure and better control comfort and safety.

› 9. The oil cylinder has been equipped with a full-range follow-up protection device to protect the oil cylinder piston rod from damage caused by falling rocks, effectively protecting the oil cylinder and extending its service life.

It is mainly used for forklifting cables, water pipes, air ducts, metal mesh and traction bracket trailers below 15T, so as to realize fast and efficient transportation of underground equipment and materials.

2. The working mechanism has a variety of accessories to choose from, and adopts a quick replacement device to quickly replace accessories, such as forks, buckets, shovels, breaker hammers, belt conveyors, trailers, etc.

3. The power system uses the American DANA double variable and drive axle, four-wheel drive, wheel side wet brakes, high safety and high reliability.

4. It is driven by a high-power explosion-proof diesel engine, which has strong power, high reliability and high safety.

| Item | Unit | WJD-1 |

| Bucket capacity | m³ | 1 |

| Rated load | t | 2 |

| Max. shovel force | KN | 48 |

| Max. traction force | KN | 52 |

| Max. unloading height | mm | 1180 |

| Min. unloading distance | mm | 860 |

| Max. bucket lifting height | mm | 3100 |

| Cable effective length | m | 95 |

| Climbing ability (full load) | ° | ≤16° |

| Min. ground clearance | mm | 190 |

| Min. turning radius | mm | Outer side 4500,Inner side 2150 |

| Working device action time | s | 12 |

| Max. steering angle (left/right) | ° | 38 |

| Departure angle | ° | 16 |

| Frame swing angle | ° | ±8 |

| Wheelbase | mm | 2200 |

| Travel speed (bidirectional) | km/h | 0-8km/h |

| Motor rated power | Kw | 45 |

| Tire specifications | 10.00-20 | |

| Dimensions (LxWxH) | mm | 6280x1300x1900mm |

| Weight | t | 7 |

| Hydraulic oil tank capacity (L) | L | 100x2 |

Henan Weibang Intelligent Technology Co., Ltd. is located in Jiaozuo New District. lt was established in 2006 with a registered capital of eighty million yuan. It is a high-end equipment manufacturing enterprise integrated scientfic research, production and sales. The company has successively established Shenzhen Besi Tiger Industry Co., Ltd., Luoyang Xinbang Technology Co.Ltd., Chengdu Taixin Zhongchuang Technology Co., Ltd., Henan Weibang Intelligent Technology Co., Ltd. and other subsidiaries, and has established 120 directly affiliated offices andfirst-level offices across the country agent. The products are widely used in the construction of mine tunnels.railways, highways, urban subways, slope engineering, water conservancy and electricity and other engineering projects. Assisting national key projects such as Shenbai High-speed Railway.Sichuan-Tibet High-speed Railway, Chongqing-Kunming High-speed Railway, Liu-Wu High-speed Railway, Xiongxin High-speed Railway, Guiping High-speed Railway, Yanyu High-speed Railway.Tianlong Railway, Yu-Wanzhou High-speed Railway, Chengda-Wanzhou High-speed Railway.

The company has long-term strategic cooperative relationships with universities and scientfic research institutions such as China Engineering Machinery Research Institute, Henan Polytechnic University, and has successively obtained 89 patents and 36 mine certfication products. In 2013, it was approved as a"National High-tech enterprise". in 2014, it was approved as "Jiaozuo Concrete Spraying and Motar Grouting Engineering Technology Center". In 2017, it was rated as a "Double 50" enterprise in Jiaozuo City, Since 2019, it has been continuously shortlisted as the annual framework supplier of many central enterprises such as China Railway and China Communications Construction Company. In 2021, he will be awarded the title of "Little Giant" for special- ization. In 2022, it was continuously approved as a "National High-tech Enterprise". lt will be approved as Henan Provincial Industrial Design Center in 2023.Taixin Company is working hard to build a collectivized industrial cluster with a new attitude and forge ahead bravely!

If you want more detail of this machine.Please send your inquiry details in the below for free sample, Click "send" Now! The best price you may get early.

|

|

|

| SSP-7 wet spraying machine | HBT pump type wet spraying machine | The vehicle mounted secondary lining pump |

आप Cooig.com पर जो भी भुगतान करते हैं वह SSL एन्क्रिप्शन और PCI DSS डेटा सुरक्षा प्रोटोकॉल के साथ सुरक्षित है

अगर आपका ऑर्डर शिप नहीं होता, गुम हो गया है या उत्पाद संबंधी समस्याओं के साथ आता है, तो रिफ़ंड का दावा करें

मुफ़्त में पार्ट्स के रिप्लेसमेंट और रिपेयर कवरेज का एक्सेस