[CODE_4]: MEDIA_ELEMENT_ERROR: Format error

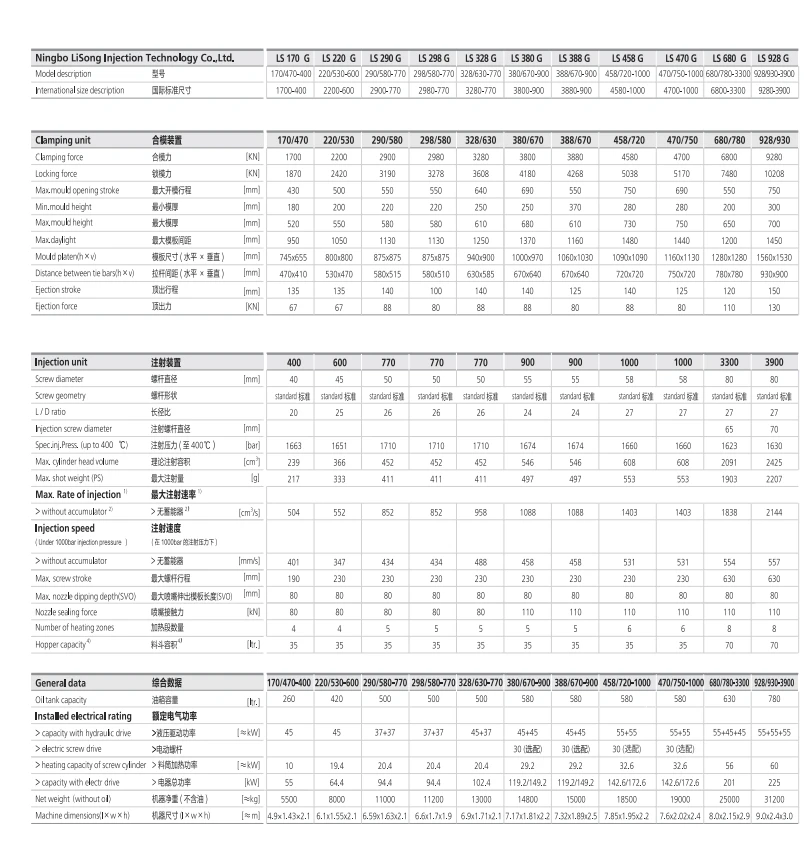

Model description | 298/350 |

item | value |

Condition | New |

Style | Horizontal |

Clamping force | 2980 KN |

Locking force | 3278 mm |

Max.mould opening stroke | 550 mm |

Min.mould height | 220 mm |

Max.mould height | 580 mm |

Max.daylight | 1130 mm |

Mould platen (h x v ) | 875 x 875 |

Distance between tie bars (h x v ) | 580 x 515 |

Ejection stroke | 100 |

Ejection force | 80 |

Injection unit | 770 |

Screw diameter | 50 |

Screw geometry | Standard |

L/D ratio | 26 |

Spec.inj.Press.( up to 400) | 1710 bar |

Max.cylinder head volume | 452 cm3 |

Max.shot weight (PS) | 411 g |

Max. Rate of Injection | 852 cm3/s |

Injection speed | 434 mm/s |

Max. screw stroke | 230 mm |

Max. nozzle dipping depth (SVO) | 80 mm |

Number of heating zones | 5 |

Hopper capacity | 35 ltr. |

Oil tank capacity | 500 ltr. |

Capacity with hydraulic drive | 37+37kW |

Heating capacity of screw cylinder | 20.4kW |

Capacity with electr drive | 94.4kW |

Net weight (without oil) | 11200 |

Machine dimensions( l x w x h) | 6.6*1.7*1.9 |

आप Cooig.com पर जो भी भुगतान करते हैं वह SSL एन्क्रिप्शन और PCI DSS डेटा सुरक्षा प्रोटोकॉल के साथ सुरक्षित है

अगर आपका ऑर्डर शिप नहीं होता, गुम हो गया है या उत्पाद संबंधी समस्याओं के साथ आता है, तो रिफ़ंड का दावा करें